- Place of Origin:

-

Guangdong, China (Mainland)

- Brand Name:

-

OEM

- Model Number:

-

MK-005

- Base Material:

-

FR-4/Aluminum, FR-4/Aluinum/CEM1/CEM3

- Copper Thickness:

-

0.5oz-6oz

- Board Thickness:

-

0.2mm–3.2mm

- Min. Hole Size:

-

0.20mm

- Min. Line Width:

-

0.1mm

- Min. Line Spacing:

-

0.1mm4mil)

- Surface Finishing:

-

HASL/ENIG

- Layers:

-

1-18layers

- Max Board Size:

-

635X1000

- Min Inner-layer Thickness:

-

0.1mm

- Solder Mask:

-

Green, Yellow, Red, Black, Blue, White

- Surface Finish:

-

HASL,Gold, Silver, Silver, Gold Finger, OSP

- Acceptable file:

-

Gerber file,CAD

- CAM software:

-

Genesis, CAM350

- Testing:

-

100%testing

- delivery time:

-

25days

- Supply Ability:

- 100000 Piece/Pieces per Month

- Port

- Shenzhen/Hongkong

- Lead Time:

- 7 days

DMX LED Controller PCB Circuit Board Assembly

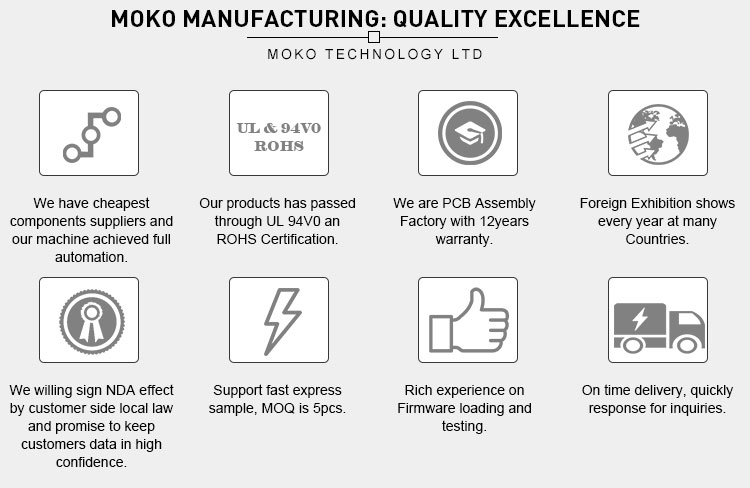

Moko Technology Ltd found in 2001, located in Shenzhen, China, who is specialized in OEM/ODM PCB&PCBA Manufacturing for 12years.

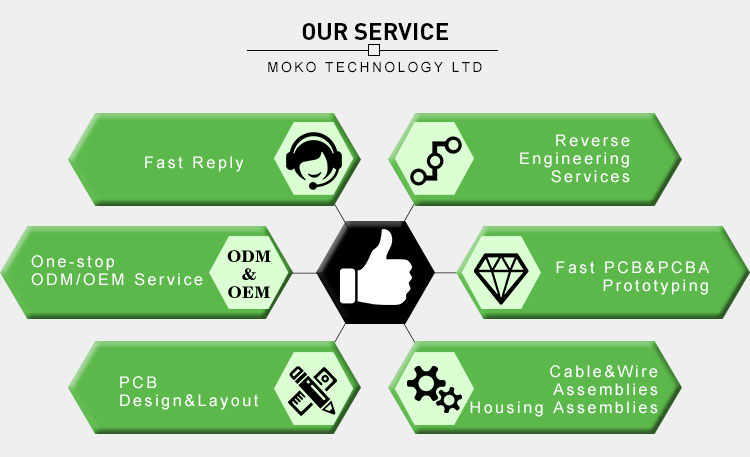

We have got the ISO9001:2008, ISO14001, and UL RoHS CE certification. Below are our services:

– Reverse Engineering Services

– Fast PCB&PCBA Prototyping

– Cable&Wire Assemblies&Housing Assemblies

– Plastics and Molds

– Function Testing

Moko factory has 8 high-speed SMT line and 3DIP line, 300workers, 20desingers and 12engineers, all sales are professional and responsible. If you’re looking for prototype PCB manufacturing&PCB assembly of high quality, Moko would be your best choice.

| Items | Device Name | Model | Brand Name | Qty | Remarks |

| 1 | Full Automatic Screen Printer | DSP-1008 | DESEN | 8 | |

| 2 | SMT Machine | YG200 | YAMAHA | 5 | 8 SMT Line |

| 3 | SMT Machine | YV100XG | YAMAHA | 3 | |

| 4 | SMT Machine | YG100XGP | YAMAHA | 19 | |

| 5 | SMT Machine | YV88 | YAMAHA | 5 | |

| 6 | Reflow Soldering | 8820SM | NOUSSTAR | 4 | |

| 7 | Reflow Soldering | XPM820 | Vitronics Soltec | 3 | |

| 8 | Reflow Soldering | NS-800 II | JT | 1 | |

| 9 | Solder Paste Inspection | REAL-Z5000 | REAL | 1 | |

| 10 | Automatic Optical Inspection System | B486 | VCTA | 3 | |

| 11 | Automatic Optical Inspection System | HV-736 | HEXI | 5 | |

| 12 | X-Ray | AX8200 | UNICOMP | 1 | |

| 13 | Universal 4*48-pindrive concurrent multiprogramming system | Beehive204 | ELNEC | 3 | |

| 14 | Automatic Plug-In machines | XG-3000 | SCIENCGO | 2 | |

| 15 | Automatic wave soldering system | WS-450 | JT | 1 | 3 DIP LINE |

| 16 | Automatic wave soldering system | MS-450 | JT | 2 |

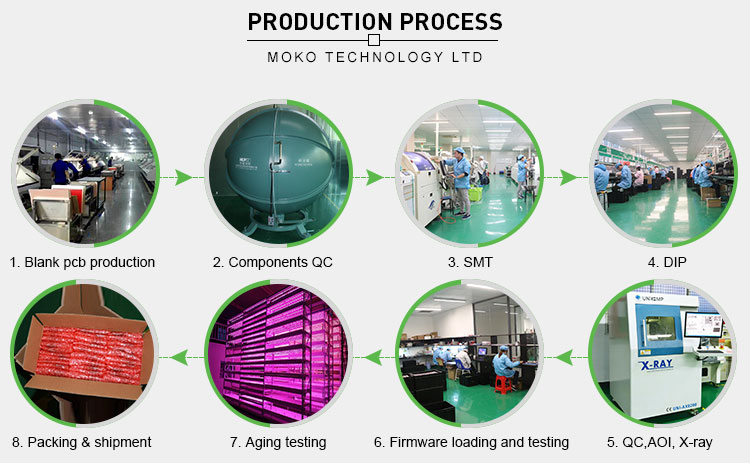

PCB Assembly Process

| Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

| Various sizes like 1206,0805,0603 components SMT technology | |

| ICT(In-Circuit Test), FCT(Functional Circuit Test) technology | |

| PCB Assembly With UL,CE,FCC,Rohs Approval | |

| Nitrogen gas reflow soldering technology for SMT | |

| High Standard SMT&Solder Assembly Line | |

| High-density interconnected board placement technology capacity | |

| Quote&Production Requirement | Gerber File or PCB File for Bare PCB Board Fabrication |

| Bom(Bill of Material) for Assembly, PNP(Pick and Place file) and Components Position also needed in assembly | |

| To reduce the quote time, please provide us the full part number for each component, Quantity per board also the quantity for orders. | |

| Testing Guide&Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

| OEM/ODM/EMS Services | PCBA, PCB assembly: SMT & PTH & BGA |

| PCBA and enclosure design | |

| Components sourcing and purchasing | |

| Quick prototyping | |

| Plastic injection molding | |

| Metal sheet stamping | |

| Final assembly | |

| Test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

| Customs clearance for material importing and product exporting | |

| Other PCB Assembly Equipments | SMT Machine: SIEMENS SIPLACE D1/D2 / SIEMENS SIPLACE S20/F4 |

| Reflow Oven: FolunGwin FL-RX860 | |

| Wave Soldering Machine: FolunGwin ADS300 | |

| Automated Optical Inspection (AOI): Aleader ALD-H-350B, X-RAY Testing Service | |

| Fully Automatic SMT Stencil Printer: FolunGwin Win-5 |

Quotation Files Request For PCB/PCBA

—In order to provide you with the most efficient and accurate quote on manufacturing the requested unit, we ask that you provide us with the following information:

1. Gerber file, PCB file, Eagle file or CAD file are all acceptable

2. A detailed bill of materials (BOM)

3. Clear pictures of PCB or PCBA sample for us

4. Quantity and delivery required

5.Test method for PCBA to guarantee 100% good quality products.

6.Schematics file for PCB design if need to do a function test.

7. A sample if available for better sourcing

8. CAD files for enclosure manufacturing if required

9. A complete wiring and assembly drawing showing any special assembly instructions if required.

Technical Capability & Support

| Layers | 1-16 layers | Min board thickness(2layers) | 0.2mm |

| Max Board size | 635*1100mm | Min board thickness(2layers) | 0.6mm |

| Min Board size | 20*30mm | Min Inner-layer Thickness | 0.1mm |

| Min Trace | 0.1mm | Min Annular Ring | 0.1mm |

| Min Space | 0.1mm | Min hole Location Tolerance | +-0.075mm |

| Min hole size | 0.2mm | Min hole size Tolerance | +-0.05mm |

| Board warp | <1 | Min Outer Dimension Tolerance | +-0.1mm |

| Solder Mask | Green, Yellow, Red, Black, Blue, White | ||

| Surface Finish | HAL, HASL, Immersion Gold, Immersion Silver, Plating Gold, Plating Nickel, Plating Silver, Gold Finger, OSP | ||

| Board Material | FR-4, High Tg FR-4, Halogen Free, FR-4, Thick Copper FR-4, Aluminium based, Rogers, Taconic | ||

| Acceptable file | Gerber file(RS-274-X or RS-274-D with aperture list and drill files), Protel, PADS, POWERPCB, AutoCAD, ORCAD | ||

| CAM software | Genesis, CAM350, Protel 99 SE | ||