| PCB Fabrication Capability |

| No |

Item |

PCB Process Capability |

| 1 |

base material |

Normal TG FR4, High TG FR4, PTFE, Rogers, Low Dk/Df etc. |

| 2 |

Solder mask color |

green, red, blue, white, yellow, purple, black |

| 3 |

Legend color |

white, yellow, black, red |

| 4 |

Surface treatment type |

ENIG, Immersion tin, HAF, HAF LF, OSP, flash gold, gold finger, sterling silver |

| 5 |

Max. layer-up(L) |

50 |

| 6 |

Max. unit size (mm) |

620*813 (24″*32″) |

| 7 |

Max. working panel size (mm) |

620*900 (24″x35.4″) |

| 8 |

Max. board thickness (mm) |

12 |

| 9 |

Min. board thickness(mm) |

0.3 |

| 10 |

Board thickness tolerance (mm) |

T<1.0 mm: +/-0.10mm ;T>=1.00mm: +/-10% |

| 11 |

Registration tolerance (mm) |

+/-0.10 |

| 12 |

Min. mechanical drilling hole diameter (mm) |

0.15 |

| 13 |

Min. laser drilling hole diameter(mm) |

0.075 |

| 14 |

Max. aspect(through hole) |

15:1 |

|

Max. aspect(micro-via) |

1.3:1 |

| 15 |

Min. hole edge to copper space(mm) |

L≤10, 0.15; L=12-22, 0.175; L=24-34, 0.2; L=36-44, 0.25; L>=44, 0.3 |

| 16 |

Min. Inner layer clearance(mm) |

0.15 |

| 17 |

Min. hole edge to hole edge space(mm) |

0.28 |

| 18 |

Min. hole edge to profile line space(mm) |

0.2 |

| 19 |

Min. Inner layer copper to profile line space (mm) |

0.2 |

| 20 |

Registration tolerance between holes (mm) |

±0.05 |

| 21 |

Max. finished copper thickness(um) |

Outer Layer: 420(12oz)

Inner Layer: 210(6oz) |

| 22 |

Min. trace width (mm) |

0.075 (3mil) |

| 23 |

Min. trace space (mm) |

0.075 (3mil) |

| 24 |

Solder mask thickness (um) |

line corner:>8 (0.3mil)

upon copper: >10 (0.4mil) |

| 25 |

ENIG golden thickness (um) |

0.025-0.125 |

| 26 |

ENIG nickle thickness (um) |

3-9 |

| 27 |

Sterling silver thickness (um) |

0.15-0.75 |

| 28 |

Min. HAL tin thickness (um) |

0.75 |

| 29 |

Immersion tin thickness (um) |

0.8-1.2 |

| 30 |

Hard-thick gold plating gold thickness(um) |

1.27-2.0 |

| 31 |

golden finger plating gold thickness (um) |

0.025-1.51 |

| 32 |

golden finger plating nickle thickness(um) |

3-15 |

| 33 |

flash gold plating gold thickness (um) |

0,025-0.05 |

| 34 |

flash gold plating nickle thickness(um) |

3-15 |

| 35 |

profile size tolerance (mm) |

±0.08 |

| 36 |

Max. solder mask plugging hole size (mm) |

0.7 |

| 37 |

BGA pad (mm) |

>=0.25 (HAL or HAL Free: 0.35) |

| 38 |

V-CUT blade position tolerance (mm) |

+/-0.10 |

| 39 |

V-CUT position tolerance (mm) |

+/-0.10 |

| 40 |

Gold finger bevel angle tolerance (o) |

+/-5 |

| 41 |

Impedance tolerance (%) |

+/-5% |

| 42 |

Warpage tolerance (%) |

0.75% |

| 43 |

Min. legend width(mm) |

0.1 |

| 44 |

Fire flame class |

94V-0 |

| Special for Via in pad boards |

Resin plugged hole size (min.) (mm) |

0.3 |

| Resin plugged hole size (max.) (mm) |

0.75 |

| Resin plugged board thickness (min.) (mm) |

0.5 |

| Resin plugged board thickness (max.) (mm) |

3.5 |

| Resin plugged maximum aspect ratio |

8:1 |

| Resin plugged minimum hole to hole space (mm) |

0.4 |

| different hole size in one board |

yes |

|

Max. panel size (finished) (mm) |

880 x580 |

| Max. working panel size (mm) |

914 x 602 |

| Max. board thickness (mm) |

12 |

| Max. layer-up(L) |

40 |

| Aspect |

30:1 (Min. hole: 0.4 mm) |

| Line wide/space (mm) |

0.075/ 0.075 |

| Back drill capability |

Yes |

| Tolerance of back drill (mm) |

±0.05 |

| Tolerance of press fit holes (mm) |

±0.05 |

| Surface treatment type |

OSP, sterling silver, ENIG |

| Rigid-flex board |

Hole size (mm) |

0.2 |

| Dielectrical thickness (mm) |

0.025 |

| Working Panel size (mm) |

350 x 500 |

| Line wide/space (mm) |

0.075/ 0.075 |

| Stiffener |

Yes |

| Flex board layers (L) |

8 (4plys of flex board) |

| Rigid board layers (L) |

>=14 |

| Surface treatment |

All |

| Flex board in mid or outer layer |

Both |

| Special for HDI products |

Laser drilling hole size (mm) |

0.075 |

| Max. dielectric thickness (mm) |

0.15 |

| Min. dielectric thickness (mm) |

0.05 |

| Max. aspect |

1.5:1 |

| Bottom Pad size (under micro-via) (mm) |

Hole size+0.15 |

| Top side Pad size ( on micro-via) (mm) |

Hole size+0.15 |

| Copper filling or not (yes or no) (mm) |

yes |

| Via in Pad design or not ( yes or no) |

yes |

| Buried hole resin plugged (yes or no) |

yes |

| Min. via size can be copper filled (mm) |

0.1 |

| Max. stack times |

4 |

![]()

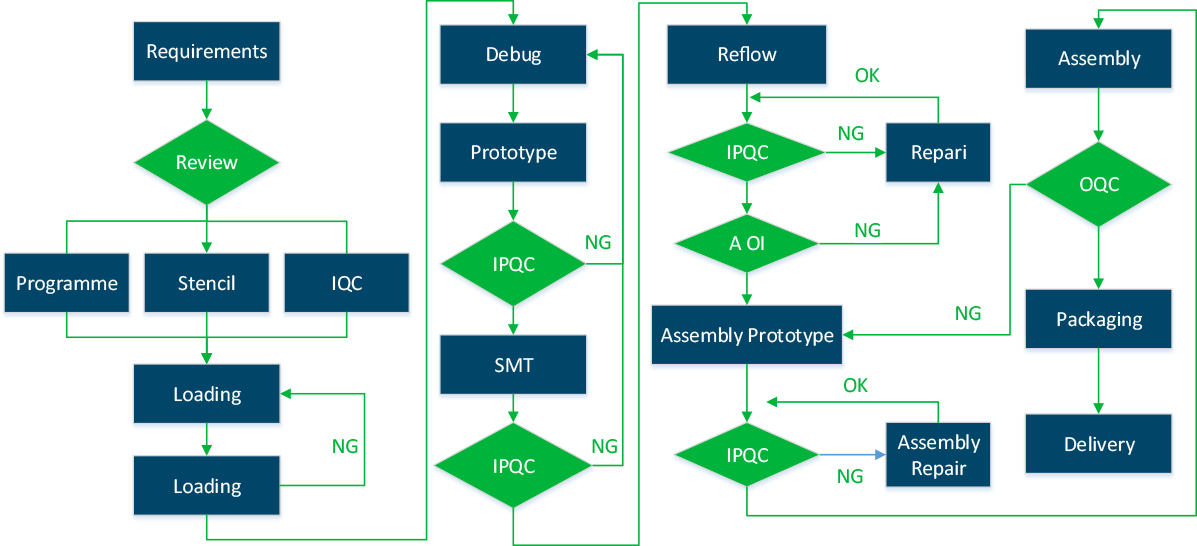

![]() SMT Assembly capability: 8 high-speed SMT lines from Yamaha and Sony(10 million chips per day-0402, 0201 with 8 million per day)

SMT Assembly capability: 8 high-speed SMT lines from Yamaha and Sony(10 million chips per day-0402, 0201 with 8 million per day)![]() DIP production capability: 3 DIP lines(1.2 million pcs per day)

DIP production capability: 3 DIP lines(1.2 million pcs per day)![]() 3 Production Lines for enclosure assembly(Each line has 15 assemblers and 2 quality control engineers)

3 Production Lines for enclosure assembly(Each line has 15 assemblers and 2 quality control engineers)![]() SMT production line: 8 SMT production lines, factory area 6000m2

SMT production line: 8 SMT production lines, factory area 6000m2![]() All SMD placements are AOI inspected

All SMD placements are AOI inspected![]() High-end equipment: YAMAHA/JT, AOI/SPI/XRAY, etc

High-end equipment: YAMAHA/JT, AOI/SPI/XRAY, etc![]() As small as 0.4mm pitch, all BGA placements are X-ray inspected

As small as 0.4mm pitch, all BGA placements are X-ray inspected![]() Full BOM material supply: RC / bead / inductor / connector / crystal / diode /transistor, etc in stock

Full BOM material supply: RC / bead / inductor / connector / crystal / diode /transistor, etc in stock![]() Minimum package: 03015, 0201, 0402

Minimum package: 03015, 0201, 0402![]() One-stop hardware innovation platform: PCB design, board manufacturing, patch assembly, component supply.

One-stop hardware innovation platform: PCB design, board manufacturing, patch assembly, component supply.![]()

![]()